Dongguan Naigu Precision Machinery Co., Ltd.

Focus on high precision gear machine tool research and development manufacturing of high-tech enterprises

0769-87191000

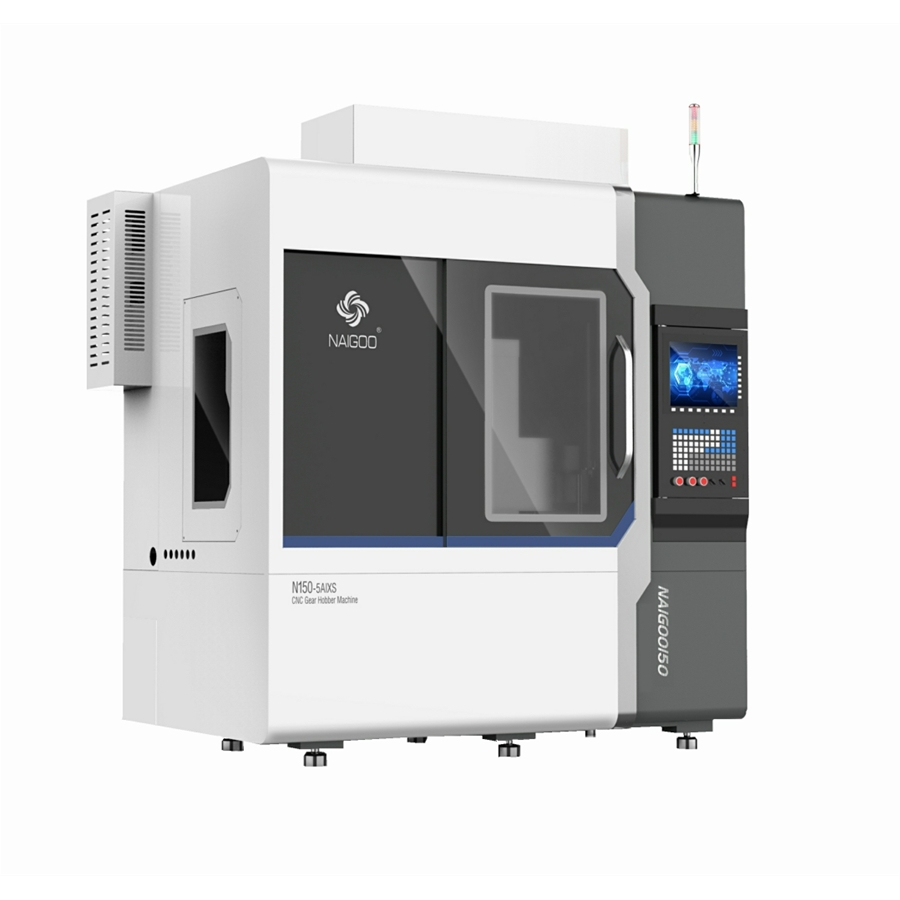

Features:

● Equipped with Higerman CNC system, electronic gear box (EBD) function and self-developed gear hobbing machine software, man-machine dialogue interface;

●The machine tool adopts vertical layout, 5-6 axis control and four axis linkage;

●B and C axes are directly connected by servo motors;

●The X and Z linear axes adopt imported H-grade precision roller guides, P-grade precision lead screws, and servo motors are directly connected, with high motion accuracy and strong rigidity;

●The Y-axis is directly connected with a servo motor, so that the tool shift can be set through the system;

●The A-axis is controlled by a servo motor and a gear reducer to increase the output torque, and the 5-axis model is controlled by a hydraulic oil pump;

●The workpiece tail top adopts hydraulic control, the pressure is adjustable, and the top tailstock has its own rotation function;

●The hob shank adopts Morse shank structure, which is convenient and quick to replace;

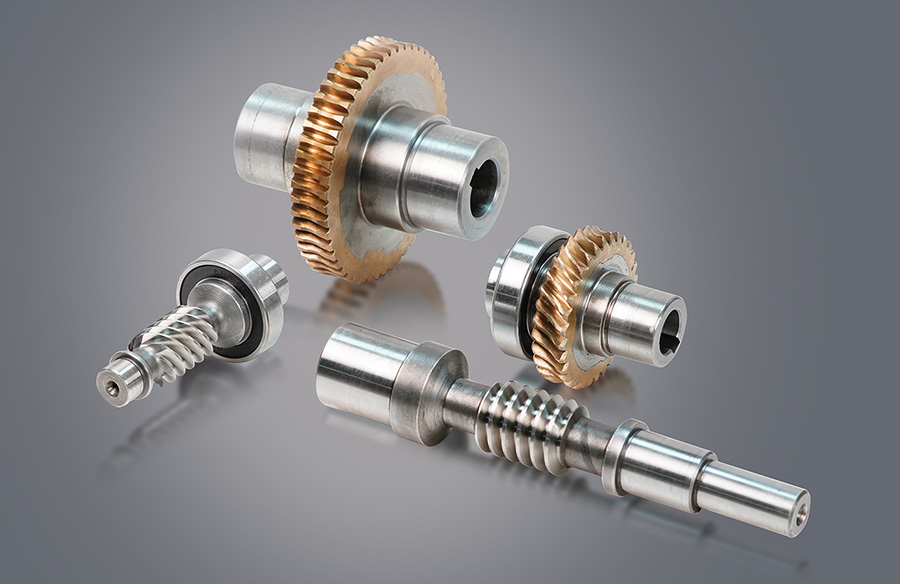

●It can process spur gears, helical gears, drum gears, worm gears, cogwheels, splines and other parts, with mass production accuracy of GB7 level and precision cutting up to GB6 level;

●Optional secondary tool setting attachment for secondary cutting of hardened tooth surface.

Machine parameters:

Machine model

Machine parameters

N150

N150D

5 axes

6 axes

5 axes

6 axes

Maximum processing module

3M

3.5M

Maximum machining diameter

¢150mm

¢180mm

Workpiece axis maximum speed (C axis)

400rpm/min

300rpm/min(DD马达)

Maximum speed of hob shaft (B axis)

2500rpm

3000rpm

Tool post rotation angle (A axis)

±45ºhydraulic

±45ºServo

±45ºhydraulic

±45ºServo

Radial stroke (X axis)

120(15-135)mm

135(20-155)mm

Axial stroke (Z axis)

350mm

300(200-500)mm

Knife shift stroke (Y axis)

100mm

90mm

Tailstock travel

400(100-500)mm

240(260-500)mm

Table diameter

155mm

160mm

hob spindle taper hole

Morse 5

Morse 5

Maximum size of hob

¢70mm*80mm

¢80mm*120mm

Radial Feed Rate (X-axis)

5000rpm/min

5000rpm/min

Axial feed rate (Z axis)

5000rpm/min

5000rpm/min

Spindle power

5.5kw

5.5kw

total power

12kw

13kw

15kw

16kw

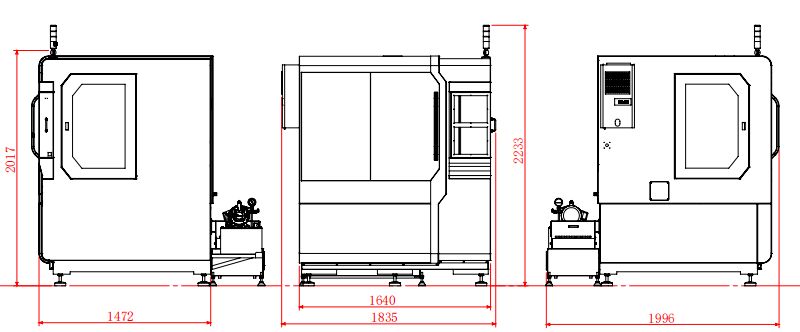

physical dimension

2200×1600×2300mm

2300×1600×2800mm

weight

about 5000kg

about 5300kg

Standard accessories:

line

Product name

quantity

1

Tool holder ¢13mm、¢16mm、¢22mm

1 set each

2

Tool spacer 10mm、20mm、30mm

1 each

3

Electric control box air conditioner

1 set

4

Clamp Mount

1 item

5

Horizontal adjustment bolt, machine foot block

6 sets

6

Standard Toolbox

1 set

7

Mohs 5 top

1 stick

8

Operating Instructions

1 set

special accessories:

line

Product name

quantity

1

Tool holder ¢27mm

1 set

2

Pneumatic hair removal device

1 set

3

Second knife setting (fine rolling)

1 set

4

oil mist collector

1 set

5

Minimum Quantity Lubrication Cooling System

1 set

6

Special tooling

1 set

7

Automatic loading and unloading system

1 set

8

Magnetic iron chip removal device

1 set

外观尺寸:

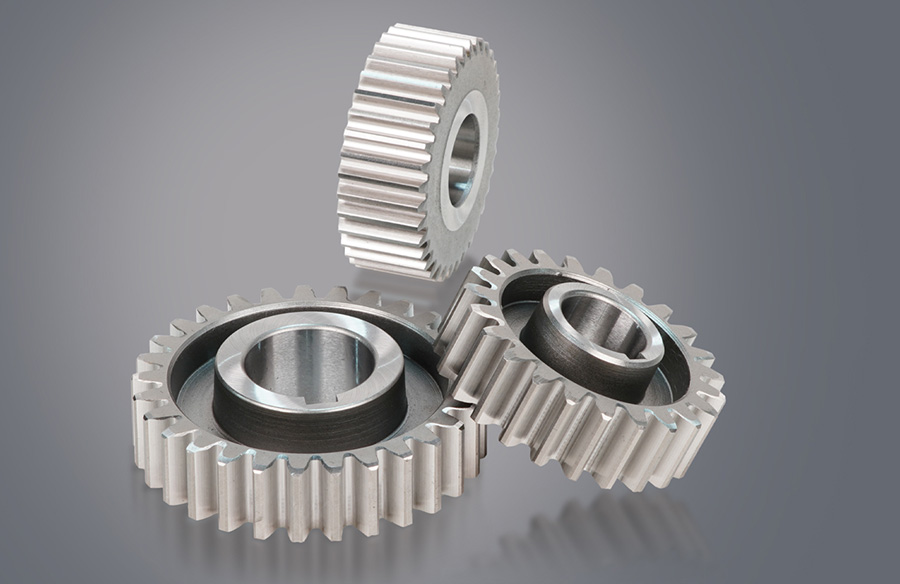

加工样品: