Dongguan Naigu Precision Machinery Co., Ltd.

Focus on high precision gear machine tool research and development manufacturing of high-tech enterprises

0769-87191000

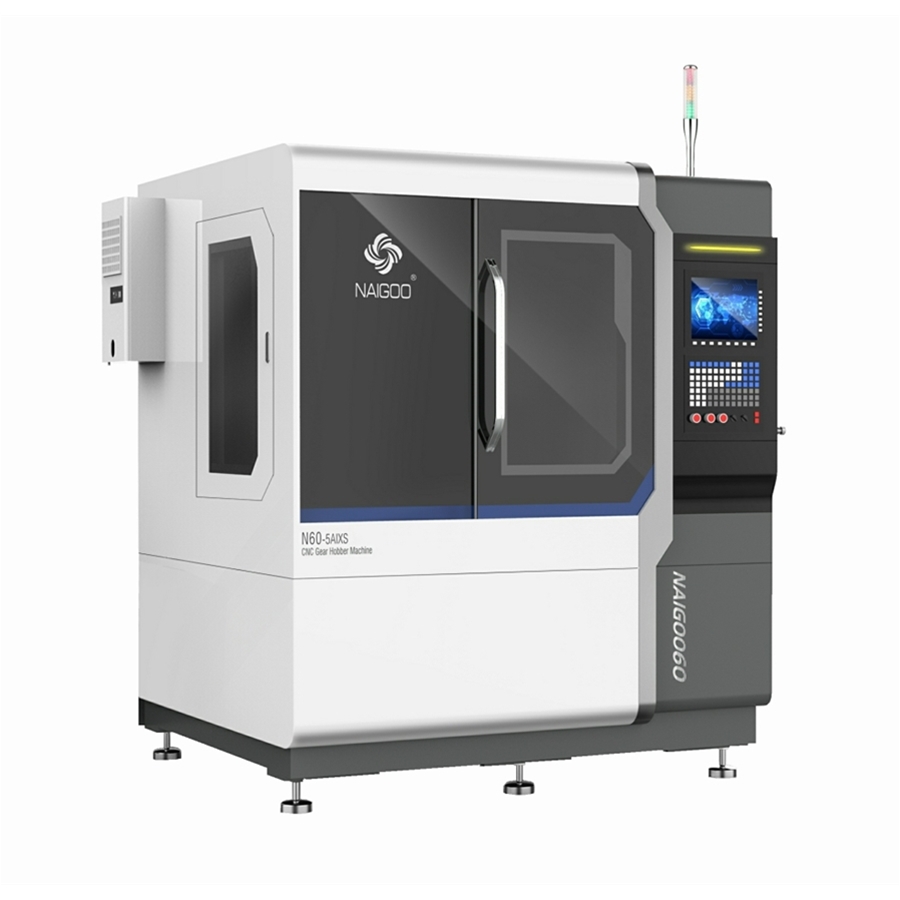

Machine Description:

N60 type 5-axis, 6-axis CNC gear hobbing machine is a gear hobbing machine controlled by 5 or 6 CNC axes. N60 type CNC gear hobbing machine is equipped with Higerman CNC system, which can process gear shafts, gears (spur gears) by generating or indexing. , helical teeth, drum teeth, synchronous teeth, bevel teeth, etc.).

The machining accuracy can reach GB/T10095-2008 grade 6 and GB/TT2363-1990 grade 6 standards, especially suitable for batch processing of small high-precision gears.

Machine features:

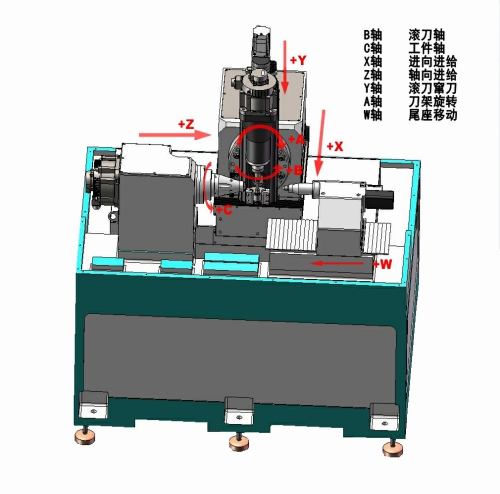

■ Full CNC Using Higerman CNC system, each motion axis of the machine tool is CNC controlled and B, C, X, Z are the linkage axes, and the electronic gearbox (program) completes the tooth division movement, feed compensation movement, and differential feed compensation movement when cutting teeth. , increased the functions of the machine tool (such as hobbing small tapers and drum gears, etc., it became extremely simple); shortened the transmission chain, and at the same time adopted semi-closed loop or full closed loop control, the positioning accuracy and repeated positioning of each axis can be improved through numerical control compensation Therefore, the machining accuracy and Cp value of the machine tool are improved, and the reliability of the machine tool is increased; when changing varieties, it saves the time for calculating and changing the gear and differential gears, feed and spindle gear shifting. The auxiliary processing time is reduced and the flexibility of the machine tool is increased.

■ High Efficiency The machine tool has a high-speed tool spindle and a high-speed worktable, while ensuring high rotation accuracy (radial runout accuracy ≤ 0.002mm, axial runout accuracy ≤ 0.002mm); greatly improve cutting efficiency; suitable for multi-head hob Powerful high-speed cutting with large amount of cutting, high processing efficiency; Adopt built-in hydraulic chuck locking device and flange-type tooling installation.

Double and multiple gears with different modules, different numbers of teeth, different helix angles and different helix directions can complete the hobbing of the teeth under one installation, and can also mill grooves with a single index;

■ High Precision A large number of imported famous brand accessories are used to improve the speed, accuracy and reliability of the machine tool. The accuracy is guaranteed and improved under processing conditions;

■ High Rigidity The machine body is made of HT300 gray cast iron with excellent wear resistance and shock absorption. It has been annealed twice to ensure dimensional stability and prevent deformation and cracking. The machine tool adopts imported HIWIN, which has a preloaded, backlash-free ball screw-driven feed system and an imported roller-type linear rolling guide with damping and preloading, which does not require maintenance and maintains high precision for a long time. Worktable indexing Adopt worm gear pair and damping mechanism with eliminating clearance;

■ Functional Compounding The workpiece can be processed in multiple processes in one clamping, thereby improving the processing efficiency and even the accuracy of the workpiece, such as: automatic feeding, gear hobbing, secondary gear hobbing, multi-process gear hobbing, deburring, and automatic blanking;

■ High Degree of Automation With automatic loading and unloading, automatic clamping device, 24-hour continuous working ability;

■ Environmentally Friendly Install the oil mist separator so that only the mist without oil is discharged;

■ Intelligence and Informatization The combination of digital control technology, sensor technology, information technology and network control technology makes CNC gear processing machine tools more intelligent. Realize the functions of error compensation, anti-collision function, overload protection, tooth meshing, machining allowance allocations, tool wear, zero programming interface, multi-function machining software, automatic identification, remote control, and remote diagnosis when robots move workpieces between machine tools ;

■ High Flexibility Short preparation time for mass production;

Product design, manufacturing and acceptance criteria:

Comply with GB/T9061-2006 General technical conditions for metal cutting equipment

Comply with GB15760-2004 General technical conditions for safety protection of metal cutting equipment

Comply with GB/T10095-2008 Grade 6 Accuracy Standard for Cylindrical Gears

Comply with GB/TT2363-1990 class 6 Standard for basic tooth profile and precision of small module involute cylindrical gears

In line with the ISO international standards in the design, manufacture and measurement of machine tools

Complies with noise level ISO 1683:2015-09

Machine tool static accuracy

* Spindle radial runout≤0.002mm; Spindle end face runout≤0.002mm;

* The concentricity between the main shaft and the tail top≤0.003mm;

* Lead screw lead error ≤ 0.008mm (full stroke), linear rolling guide accuracy ≤ 0.003mm;

* Repeated positioning accuracy of Z and X axes is ±0.002mm;

* Machining gear accuracy grade: GB/T10095-2008 grade 6 and GB/TT2363-1990 grade 6.

Machine parameters:

Machine model

Machine parameters

N60-5 axis

N60-6 axis

workpiece

Processing module range

0.15-2.0M

Processing tooth range

3-999Z

Maximum machining diameter

120mm

Maximum processing length

180mm

Maximum installation length

300mm

C-axis (workpiece spindle) speed

1000rpm

knives

B axis (hob spindle) speed

3000rpm

Maximum length of hob

60mm

Maximum diameter of hob

60mm

B-axis (hob holder) rotation angle

+65º/-50ºmanual

+65º/-50ºautomatic

journey

Y-direction knife stroke

60mm

X-axis (radial) stroke

90mm

X-axis (radial) feedrate

5000mm/min

Z-axis (axial) stroke

180mm

Z-axis (axial) feedrate

5000mm/min

power

Spindle power

3kw

total power

13kw

14kw

size and weight

physical dimension

2000×2200×2000mm

2000×2200×2000mm

weight

3800kg

3800kg

line

Product name

quantity

1

Tool holder ¢13mm

1set

2

Tool spacer 15mm

2pcs

3

Hydraulic clamping tool seat

1set

4

Adjusting Bolt Machine Foot Block

6pcs

5

Standard Toolbox

1set

6

Standard collet ¢10mm

1pcs

7

Mohs No. 2 full circle top

1pcs

8

Pneumatic hair removal device

1set

9

Rotating tail top

1set

10

Operating Instructions

1set

line

Product name

quantity

1

Tool holder ¢10mm、¢22mm

1pcs

2

second knife

1set

3

oil mist collector

1set

4

Magnetic iron chip removal device

1set

5

Minimum Quantity Lubrication Cooling System

1set

6

Special tooling

1set

7

Automatic loading and unloading system

1set

Standard accessories:

Special accessories:

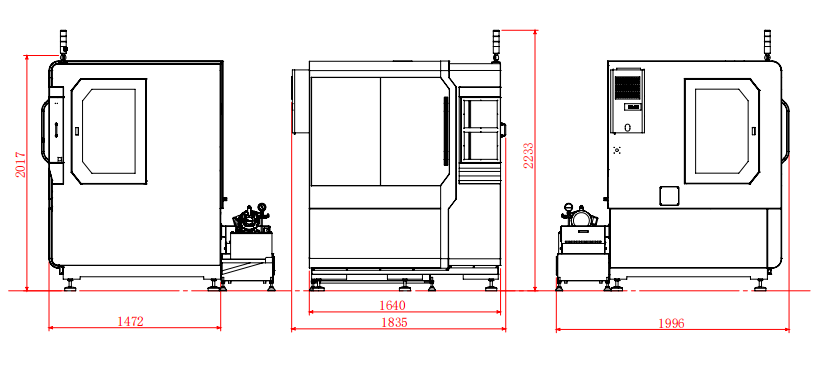

Physical dimension:

Processed products: